Vista Seal IT

Dr Vista Seal-IT is based on liquid polysulphide polymers, which adhere to most of basic civil engineering materials like cementitious substrates, aluminium, glass, wood, mild steel etc. The product is used for sealing expansion joints, door window surrounding joints & floor concrete to wall masonry separation joints etc. After mixing the base component & curing agent in given proportion rubber like material is formed. It conforms to BS 5212: 1990 Part I -Type F and Type FB (Flame and Fuel Resistance). Also complies IS 12118 Part 1 – 1987.

Application :

Vertical & Overhead expansion joints in Industrial, commercial or residential buildings.

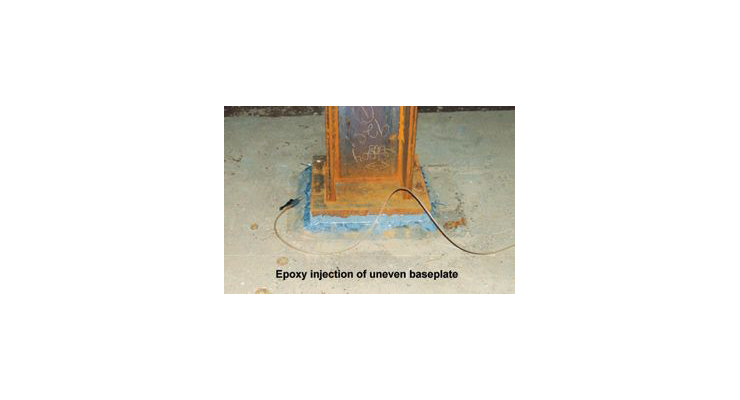

Joints in concrete roads bridges, subways, flyovers & airport runway.

Joints between plastered masonry walls & aluminium door/window section sides.

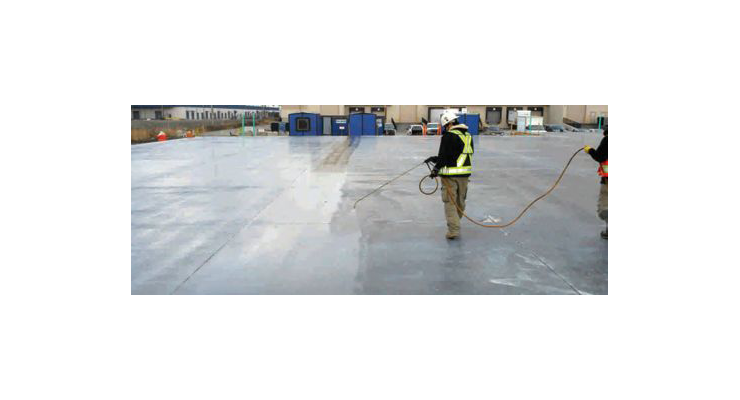

Concrete cracks repairs in slab.

Joints in water retaining structures like water tank, swimming pool, aqueducts, dams, canals & reservoirs.

Atomic nuclear power station reactor domes.

Joints between pipe lines.

Roof light joints.

Advantages :

Excellent UV resistance after full cure is over.

Can withstand in fully submerged condition.

Good chemical & water resistance.

Adhesion compatible to most of substrate.

Suitable for potable water after full cure.

Very high thermal flexibility.

Very high service life.

Flame and Fuel Resistance

Application Methodology :

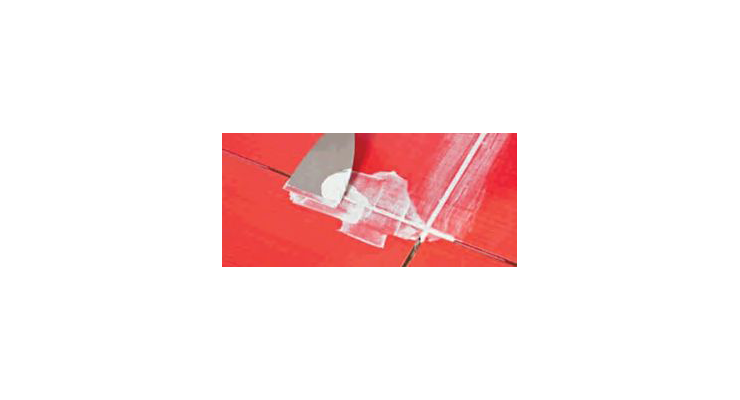

Surface should be fully dry, clean and free from dust, oil and grease etc.

Clean with sand paper & wire brush, then dust and foreign particles to be removed.

Subsequently use masking tape at floor level beside both sides to get sharp edged neat and clean joint.

Use polyurethane Foam (PUF) strips (equivalent) in expansion, construction & control joints as back up material to avoid 3-face adhesion and to avoid contact between joint forming board & sealant.

Use of primer on vertical side faces of the joint is optional to ensure strong bonding between substrate and sealant. Primer must be recommended for old concrete.

Sealant application should start after 30 minutes but not later than 2 hours after priming the surface.

The Base and Accelerator compounds are packed in pre-weighed quantity as per the mixing ratio.

Mix the material of individual container.

Transfer entire quantity of Accelerator to the base compound and mix it thoroughly to a uniform and homogenous Grey colour.

Mixing can be done manually with spatula/palette knife or special flat stirrer attached to a low speed electric mixer less than 500 rpm.

Finishing and Cleaning : Finish the joint in concave shape by using wooden batten soaked in soap water or white sprit from time to time. Remove masking tape within 30 minutes before setting of sealant. Clean tools and tackles using solvent like Xylene etc.

Health & Safety :

Dr Vista Seal-IT and primer may cause sensitisation by inhalation and skin contact.

Wear suitable clothing, gloves and eye/face protection. Barrier creams provide additional skin protection.Any skin contact occurs; remove immediately with a resin removing cream, followed by soap and water. Do not use solvent.

Fire : Primer is flammable. Do not expose flames or other sources of ignition. No smoking.

Containers should be tightly sealed when not in use. In the event of fire, extinguish with Co2 or foam.