Vista Macro Synthetic

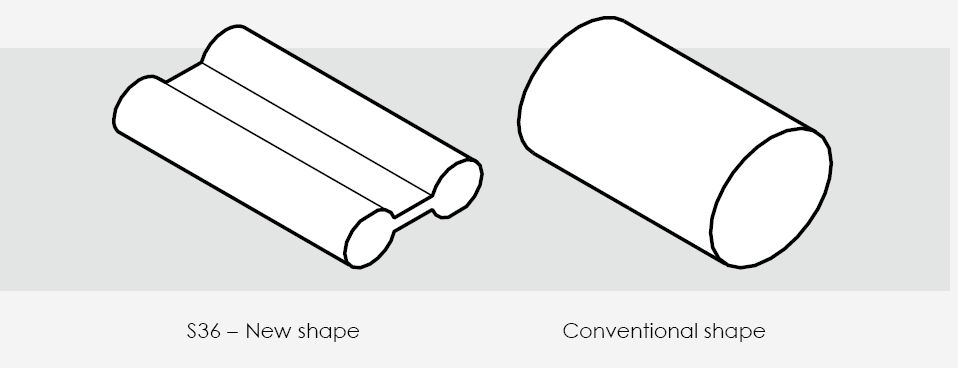

Engineered to replace steel mesh or steel fibres in precast and sprayed concrete, ground supported internal slabs and external hard standings, Dr Vista S36 is the latest addition to the range of embossed macro synthetic fibres. Thanks to a unique fibre shape and state-of-the-art extrusion technology applied in the manufacture of Dr Vista S36 this fibre is outperforming its alternatives.

Why choose Dr Vista S36 ? Dr Vista S36 is the result of extensive in-house research & development work and in-depth performance testing by independent laboratories. This fibre is raising the bar for concrete reinforcement using macro synthetic fibres:

- Greater tensile strength per fibre

- More fibres per m3 due to smaller fibre diameter

- Maximum bond within concrete thanks to innovative fibre design

- Creates enhanced residual flexural strength and toughness in the concrete

- As all other fibres offered by Dr Vista S36, also Dr Vista S36 comes with far-reaching technical advice and design support offered by Dr Vista experienced design team.

Advantages & Benefits : The benefits, which macro synthetic fibres bring to construction sites around the world are numerous. Examples encompass :

- Easy to transport, store and handle

- Improved safety on site

- Increased speed of construction

- High alkali, acid and salt resistance

- Chemically inert and stable

- Easy to finish

- Reduced carbon footprint (116-309 kg/m3 for steel vs. 2-2,6 kg/m3 for fibres)

Dr Vista has engineered Dr Vista S36 into an innovative fibre shape creating an increased specific surface. This design is outperforming conventional round shaped macro synthetic fibres. Another plus is the reduced thickness and enhanced strength of Dr Vista S36 fibres. They make for a significantly increased amount of fibres per m3, thus creating improved concrete reinforcement over conventional fibres.

Packaging & Dispersing : Dr Vista S36 fibres are packed into pucks wrapped in a water soluble film. Cased into paper bags, they can be tipped complete with the fibres directly into the concrete pan mixer or truck mixer. The dosage rates are dependent on the specific application. Dr Vista offers flexible packing configurations to suit the dosage and type of concrete plant.

Mixing Directions : The fibre is best dispersed when added to a forced action pan mixer or equivalent, prior to discharging the concrete into a truck. It is suggested that you contact your Dr Vista representative to discuss the preferred mixing method.

Storage : Dr Vista S36 must be stored on a clean surface in dry conditions and protected from potential sources of damage.

Quality Assurance : Dr Vista S36 complies to EN 14889 – 2 : 2006 (EC Certificate of Conformity). The Quality Management of Dr Vista has been approved to the ISO 9001 & 14001 Quality Management System Standards. Dr Vista products are manufactured to exacting standards on technologically advanced production and packaging lines allowing constant monitoring of quality.

Call today to find out how you can take advantage of Dr Vista S36 with your next project : Any and all data of this publication can be subject to change without notice and are provided strictly as information only, without charge or obligation and/or without any warranty or representation whatsoever, express or implied, as to the suitability for any use, accuracy, reliability or completeness. Because the use of the data can vary and is beyond our control, the recipient shall assume full responsibility of his use and we decline any liability or warranty for damages and/or losses of whatever kind incurred by whomever in connection with or arising from the use, the result of use or inability to use the data of this publication.

Specifications

| Fibre Length | 48 mm or 55 mm |

| Chloride Content | Zero |

| Elastic Modulus | 5740 MPa -574 MPa EN 14889-2 |

| Tensile Strength | 417 MPa -31 MPa EN 14889-2 |

| Colour | White |

| Electrical Conductivity | Zero |

| Specific Gravity | 0.905 |

| Absorption | Zero |

| Shape | Embossed elongated design |

| Fibre Type | Macro monofilament |

| S03 Content | Zero |