Vista Crackstop Monofilament Fibre

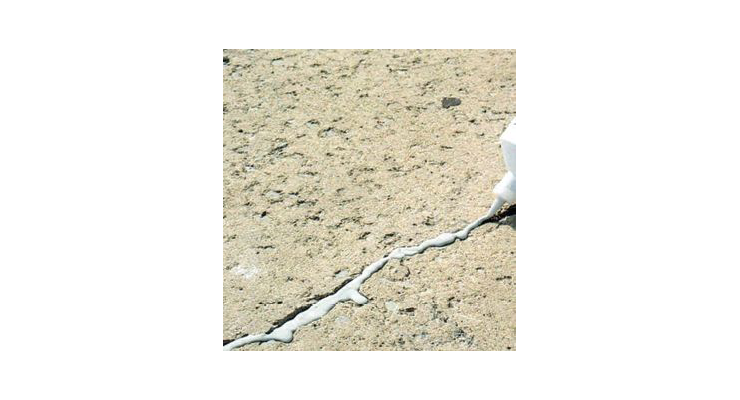

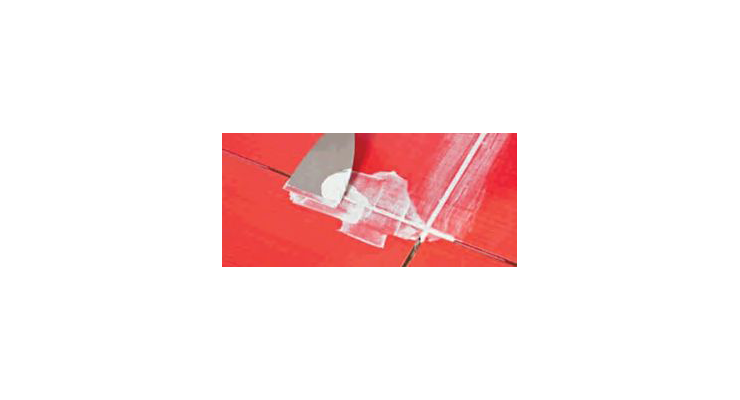

The Crack stop range of monofilament polypropylene fibres reduce the occurrence of plastic shrinkage and plastic settlement cracking, whilst enhancing the surface properties and durability of hardened cementitious products. Crack stop fibres are extremely fine, single filaments, cut to lengths of either 3, 6, 12 and 18 mm. Some fibre types also have blended lengths. The fibres are coated with surfactant to improve initial dispersion within the cementitious materials.

Advantages & Benefits

- Reduced plastic shrinkage cracking

- Reduced explosive spalling in fire

- Alternative to crack control mesh

- Improved freeze/thaw resistance

- Reduced water & chemical permeability

- Reduced bleeding

- Reduced plastic settlement cracking

- Increased impact resistance

- Increased abrasion properties

General Applications

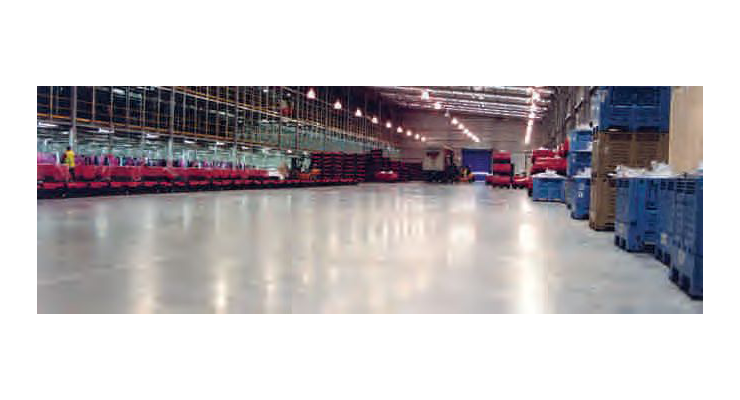

- Internal floor slabs

- Concrete framed buildings

- External hard standings

- Bridges

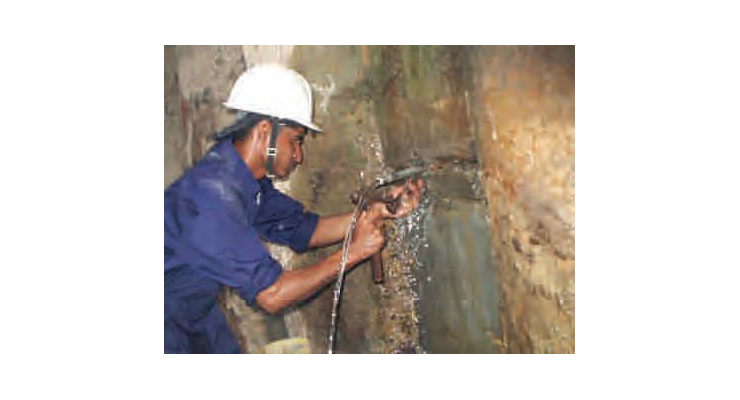

- Underground construction

- Agricultural areas

- Self compacting concrete & screeds

- Water retaining structures

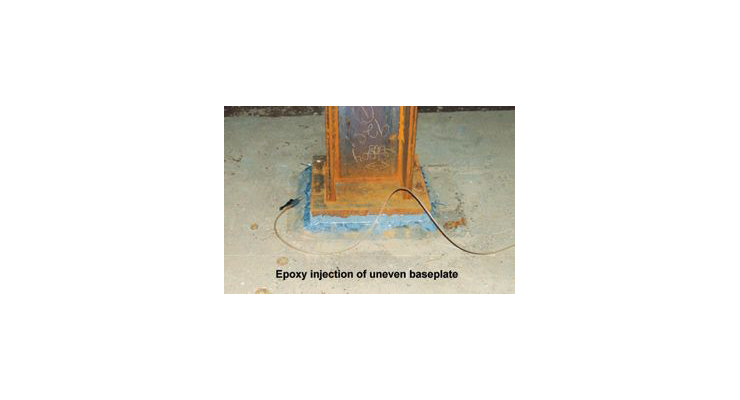

- Repair materials

- Pattern imprinted concrete

- Precast concrete

- Extruded concrete

- Piling concrete

- Shotcrete/gunite

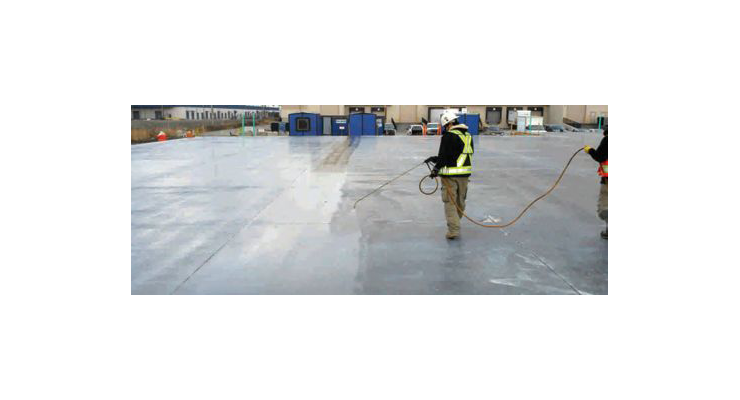

Mixing Directions : Crack stop fibres should ideally be added at the batching plant although in some instances this may not be possible and addition at site will be the only option. If mixing at the batching plant, fibres should be the first constituent, along with half the mixing water. After all the other ingredients have been added, including the remaining mixing water, the concrete should be mixed for a minimum of 70 revolutions at full speed to ensure uniform fibre dispersion. In the case of site mixing, a minimum of 70 drum revolutions at full speed should take place.

Packing & Dispensing : Crack stop fibres are packed in the desired measured quantities in either degradable/pulpable paper bags or plastic bags. The paper bags can be added to the truck or plant mixer unopened. Plastic bags will need to be opened and the fibres added manually. Bagged fibres are placed in boxes for ease of handling. Crack stop fibres can also be ordered in bulk quantities and packed in boxes or super sacks of various sizes between 20-200 kg. The larger units are specifically designed for projects where fibre dosage machinery is available.

Storage : Crack stop fibres must be stored on a clean surface, in dry conditions, under cover and away from the possibility of damage.

Quality Assurance : The Quality Management Systems of Dr Vista facilities have been approved to the ISO 9001 Quality Management System Standard. Certificates are available on request. Dr Vista products are manufactured to exacting standards on technologically advanced production and packaging lines, which allow constant monitoring of quality. Quality audits are conducted at our manufacturing plants.

Technical Advice : Our technical specialists are available to assist you in the correct use of all Dr Vista products.

Design Service : For all concrete floor design requirements please consult your Dr Vista representative.

Total Solution Provider : We offer a full design service for Dr Vista products. Our expertise and knowledge of the construction industry means that we can offer our customers bespoke solutions in terms of engineered proposals, concrete mix designs, packaging configurations, high standards of distribution and fibre dosage equipment.

Specifications

| Material | 100% virgin polypropylene |

| Design/shape | Monofilament fibre with a diameter of 22 μm max. |

| Fibre Length | 3, 6, 12, 18 mm nominal or blended lengths |

| Surface | Coated for dispersion |